- Home Page

- Company Profile

-

Our Products

- Aluminium Guide Roller

- Rotogravure Printing Roller

- Rubber Expander

- Cork Industrial Rollers

- Hot Cast Polyurethane Roller

- Solventless Printing Roller

- Pop Reel Rubber Expander Roller

- Charge Roller

- Grooved Spreader Roller

- C Style Safety Chuck

- Ebonite Rubber Roller

- Pinch Roller

- MS Steel Roll

- Polyband Expander

- Tissue Paper Embossing Roller

- Rubber Grooved Spreader Rollers

- Slitter Rewinder Shaft

- Guide Roller

- Foot Mounting Safety Chuck

- Male Female Embossing Roller

- HCP Roller

- Flange Mounting Safety Chuck

- Glass Embossing Roller

- Paper Embossing Roller

- Banana Roller

- Spiral and Straight Groove Rollers

- Slat Expander Roll

- Bowed Spreader Roller

- Bow Banana Spreader Roller

- Urethane Rollers

- Ink Transfer Roller

- Aluminum Anodized Roller

- Wrinkle Remover Expander Roller

- Idler Roller

- Drying Range Cylinder Rollers

- Leather Embossing Roller

- Adhesive Coating Rubber Roller

- Aluminium Guide Roller

- Aluminium Anodized Roller

- Metal Expander Roller

- Etching Roller

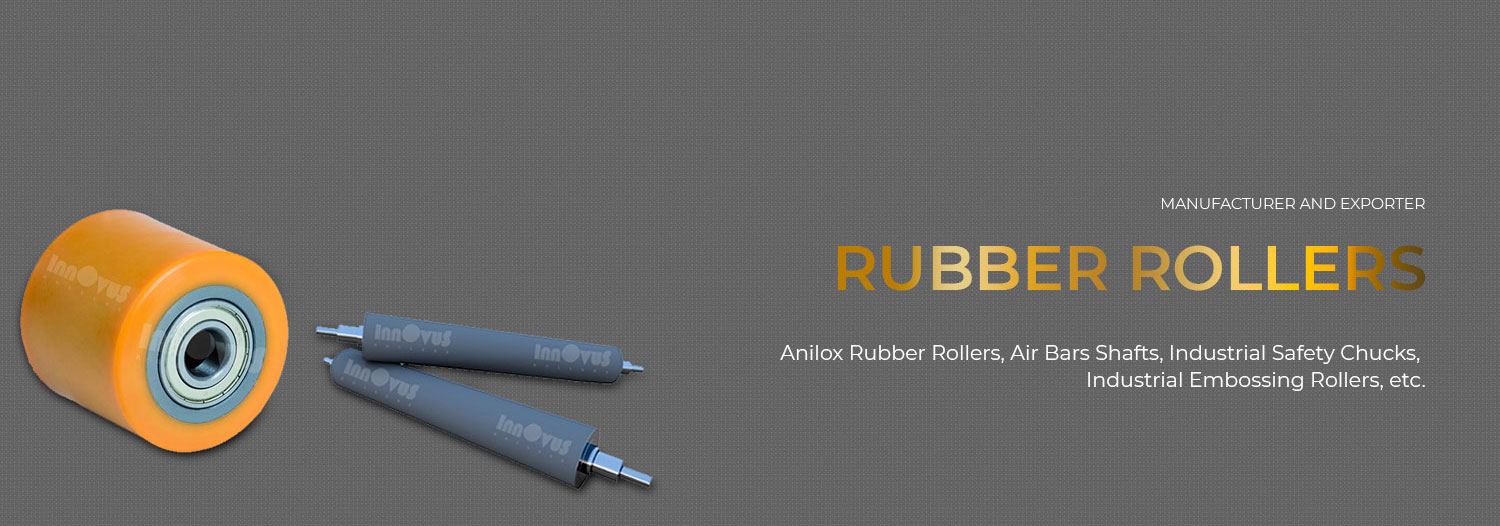

- Rubber Rollers

- Rubber Conveyor Rollers

- Industrial Nitrile Rubber Roller

- EPDM Rubber Roller

- Printing Rubber Roller

- Nitrile Rubber Roller

- Industrial Butyl Rubber Roller

- Industrial Silicone Rubber Roller

- Textile Rubber Roller

- PU Roller

- Anilox Rubber Roller

- Rubber Roller

- Industrial Rubber Expander Roller

- Polyurethane Rubber Roller

- Natural Rubber Roller

- PU Rubber Roller

- Industrial Polyurethane Rubber Roller

- Industrial Rubber Rollers

- White Epdm Rubber Roller

- Air Shaft

- Embossing Rollers

- Hardchrome Plating Roller

- Safety Chuck

- Aluminium Guide Roller

- Contact Us

Pinch Roller

Product Details:

- Diameter 50 mm

- Capacity Heavy Duty

- Usage Industrial

- Material High Quality Rubber with Metal Core

- Product Type Pinch Roller

- Dimensions Customized as per requirement

- Technique Precision Moulded

- Click to View more

X

Pinch Roller Price And Quantity

- 1 Piece

- INR

Pinch Roller Product Specifications

- Industrial Grade

- High Wear Resistance, Precision Ground Surface

- High Quality Rubber with Metal Core

- Customized as per requirement

- Industrial

- 50 mm

- Pinch Roller

- Black

- Heavy Duty

- Up to 200 mm

- Precision Moulded

Pinch Roller Trade Information

- All India

Product Description

Specification

- Hardness:as per customer requirement

- Color:as per customer requirement

- Material:as per customer requirement

- Brand:Innovus Rollers

- Length:as per customer requirement

- Weight:as per customer requirement

- Outer Diameter:as per customer requirement

- Roller Length:as per customer requirement

Smooth, Durable Surface for Industrial Operations

The Pinch Roller boasts a precision ground smooth surface and a hardness rating of 60-70 Shore A. This construction provides excellent grip and longevity, ensuring that conveying, laminating, and pressing processes are efficient and effective, even under demanding conditions. Its precision moulded technique promotes uniform performance and minimizes product wear over time.

Versatile and Robust Design

Suitable for a wide range of belt widthsup to 200 mmand shaft-mounted for secure installation, our Pinch Roller can be tailored to your specific dimensions. The heavy-duty metal core and high-quality rubber offer optimal durability, making it suitable for industries where reliability and consistent output are essential.

Reliable Performance in Extreme Conditions

Engineered for industrial use, these rollers operate seamlessly in temperatures ranging from -10C to 80C. Their high wear resistance and industrial grade standard make them dependable for continuous operation, providing a reliable solution for manufacturing and processing facilities across various sectors.

FAQs of Pinch Roller:

Q: How is the Pinch Roller installed in industrial machinery?

A: The Pinch Roller is designed for shaft mounting, which ensures stable attachment and easy integration with industrial conveyors, laminators, and pressing equipment. Installation involves sliding the roller onto the compatible shaft and securing it according to machinery specifications.Q: What materials are used in manufacturing the Pinch Roller?

A: The roller is made from high-quality rubber for optimal resilience and a durable metal core for structural strength, ensuring heavy duty performance in demanding industrial settings.Q: When should I use a Pinch Roller with 60-70 Shore A hardness?

A: A Pinch Roller with 60-70 Shore A hardness is ideal when you require a combination of flexibility and firmness for operations such as conveying, laminating, and pressing, particularly with belt widths up to 200 mm and in conditions demanding high wear resistance.Q: Where can the Pinch Roller be utilized?

A: Pinch Rollers are widely used in industrial facilities for material handling, laminating sheets, and pressing operations. They are suitable for any application that requires precision movement and pressure along a belt or substrate.Q: What benefits does the precision ground surface provide?

A: The precision ground surface delivers consistent contact, minimizes slippage, and enhances product quality during conveying, laminating, or pressing, resulting in uniform processing and less material waste.Q: Which process is used to manufacture the Pinch Roller?

A: The rollers are manufactured using precision moulding techniques, which ensure accurate shape, size, and surface finish according to specific industrial requirements and custom dimensions.Q: How does high wear resistance contribute to roller longevity?

A: High wear resistance ensures the roller can withstand repetitive motion and friction, reducing downtime due to maintenance or replacement and optimizing the long-term operational efficiency of your industrial processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free